concept & research

At the beginning of the project, we wanted to challenge ourselves to bring static objects to life. We really wanted to merge the beauty of photorealistic rendering availble to Maya with the magic of animation. We had to select a theme that matched. We selected a paint company and used the theme of the Olympics to bring it together. We took inspiration from viewing footage of previous Olympic games as well as advertisements presented for the upcoming Rio games. The footage from previous Olympic competitions helped us develop our characters their range of motion, giving each character their individual personality.

production

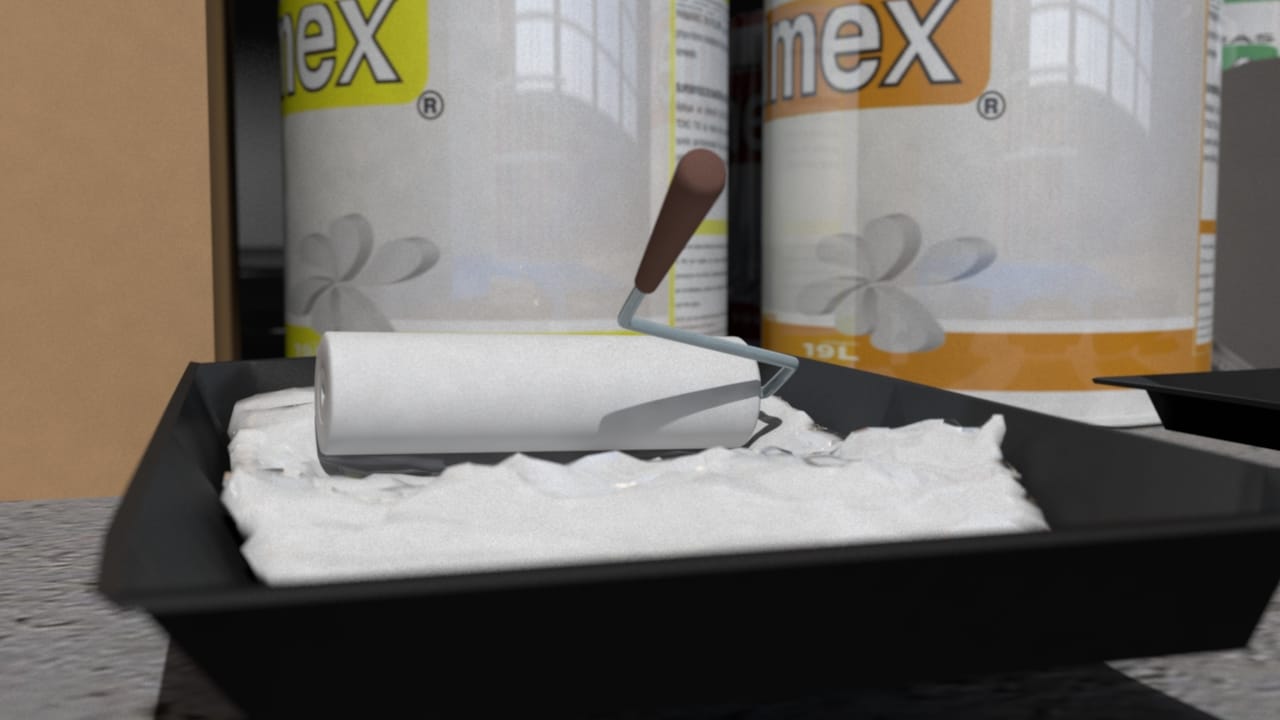

We started off by developing a storyboard that included different actions for the characters, mimicking sports such as diving, track, syncroized swimming. At the same time, we started modelling the characters including paint buckets, brushes, and spray paint cans in Autodesk Maya.

Once our project has been greenlit for production, we modelled out our set, a remote factory and the rest of our characters. We started blocking out the motions for each of the characters as well as applied shaders and textures. We then producted a quick animatic to help us better block out the shots and time the final production. This gave us the advantage to determine how long each shot and action should be, which saves us from rendering extra frames.

Along with the animatic, we included a few still frames with the final artpiece obfuscated and shown in black.

challenges

We faced two major challenges in the creation of this project, the first was the simulation and rendering of water, the second was the time it took to render our project. We researched different solutions to simulate water, the first was Realflow, the more realistic of the two solutions, and the other using nCollider objects. Unforunatley, Realflow required too much simulation time, an estimated 6 to 8 hours to simulate each of our two shots. We ended up using the built in nCollider simulation to a fairly decent result.

Our other challenge was much more pesky, we had issues with our render times. Our entire project is about 2300 frame. We estimated it would take 7 days of non-stop rendering on 6 computers. When we started rendering our final project with all the final lighting and quality, each frame was taking up to 35-40 minutes. That meant it would take us using an entire lab of computers 7 days straight of rendering and without failing to complete the rendering of the project.

We realized that, not only was that not feasible for us to take up that much lab time as the labs are shared with classes, but it would not account for failed renders or any errors.

We solved the issue by using offshore rendering services, RebusFarm and Fox Renderfarm. They were capable of rendering over 100 frames simultaneously and do each frame in half the amount of time. Thus, we were able to fully finish rendering over the 7 days, giving us time to tweak and re-render any failed shots.